|

All About Chocolate > Cocoa - from bean to paste

Climate: tropical. The "cocoa belt," as it is called, includes the 20th, 21st and 22nd parallels and extends from South America to Malaysia, including the Ivory Coast, Nigeria and Cameroon. Cocoa was introduced to the Caribbean by Benjamin Dacosta, and it was here that the tree was successfully acclimated in the 17th century.

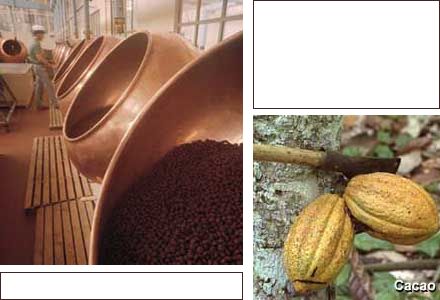

Cocoa trees are small undergrowth trees with a rough bark, covered in large long leaves, among which a few, very young, look like little rose flowers that contrast with the long curved yellow fruit that looks like a rugby ball, and which bends the stalks with its weight.

The cocoa tree blooms year-round. It is covered with thousands of little flowers a year, white or saffron-colored, with no scent. However, not all the flowers produce pods. Most dry up and die. In fact, the cocoa tree naturally controls its production. Out of thousands of flowers, only about 1% will become pods. Cultivated cocoa trees produce 24 pods a year on average. It takes 4-6 months for them to ripen. Their color varies by variety and ripeness. They are harvested every 6 months between May and July and between November and December, depending on the country of growth.

The pods are large, ovoid, ridged and turn dull gold in color when ripe. Their size ranges from 12 to 30 cm in length and 7 to 13 in width. Each contains 20 to 40 beans in a sweet-sour pulp that varies from dark brown to white depending on the number of Criollo genes in the plant.

There are three varieties of beans:

Just as with coffee, there are good, and less good, cocoa beans, although this differentiation is relatively recent.

- Criollo - attractive aromatic red beans, these are the ne plus ultra of chocolate making, used in deluxe chocolate. They are grown in Mexico, Madagascar, Venezuela and Ecuador. The beans are light and large, the pods green, turning orange when ripe. It is a sensitive and disease-prone variety and accounts for only 1% of production worldwide.

- Forastero - a less noble, but very resistant variety that produces bitter, full-flavored cocoa. It is used in 80% of world chocolate making and is grown mostly in Brazil, Malaysia and west Africa. The beans are violet and the pods most often green, turning yellow when ripe.

- Trinitario - a cross between Criollo and Forastero, it is found everywhere in the cocoa belt, but was born in Trinidad in 1939, thus its name. Excellent quality, combining the qualities of the two preceeding varieties. Represents about 20% of global production.

Cultivation

Cocoa requires a warm wet climate with regular rainfall, and deep, fertile, well-drained soil. Cocoa trees also require a lot of shade, which is why, near cocoa plantations in Trinidad and elsewhere, you'll see tall vine-covered trees protecting the delicate cocoa bushes.

The cocoa tree is grown preferably at between 400 and 700 m in altitude, in the equatorial and tropical zone between 20° north and 20° south. It produces 300 to 1000 kg of cocoa per hectare. It can start producing fruit after 3-4 years; it is fully mature at 10 years old and will produce for about 50 years.

Harvest

In December and July the pods turn from green to yellow or light red. It is harvest time. Using a long knife, workers first knock the pods from the trees. The beans are removed and piled in their baskets or jute sacks. The weight collected determines their wage for the day.

Processing steps

- The beans are first sorted, cleaned and fermented for 4-6 days in wooden cases covered in banana leaves. This first fermentation allows the pulp around the beans to liquefy.

- Then comes the second fermentation. The alcoholized pulp turns into vinegar. The bean is cleaned and the fermentation stopped. They are transferred to a new container to aerate them. Poor fermentation gives the beans an unpleasant astringent, bitter taste.

- The beans are then dried. There's nothing like 3 days in the sun. Then the women's work begins, breaking up the lumps of agglomerated beans and removing any rotten ones. Trying to rush the drying process over a wood fire will give the beans a smoky flavor.

- Then comes the turning. Once they were trampled by foot, like grapes.

- Finally, calibration. Flat or oddly shapen beans are sent to be made into powder or cocoa butter. Plump beans are put into bags to be sent to the big roasteries.

- The final step allows the flavors to be improved before crushing the beans. The moisture is removed and the aroma enhanced through roasting, with the time and temperature determined by the variety of cocoa.

- The beans are then crushed to remove the seed from the hull.

- Grinding: the debris is removed and the beans are transformed into paste.

- Under the effects of heat and pressure, the cocoa releases its fat which accounts for about half its weight.

- Now comes kneading: cocoa butter and sugar are incorporated. The proportions are important. Bitter chocolate should never be more than 40% sugar.

- Then comes "conching," in which the chocolate is processed by rollers at 80° C for a whole day, and for deluxe chocolate, up to 5 days.

- Crystallizing the cocoa butter by heating it gives the chocolate its shine. It is then poured into moulds.

Producing countries

- Côte d'Ivoire - 35.8 %

- Ghana -10.3 %

- Cameroon - 4.0 %

- Brazil -10.9 %

- Malaysia - 8.3 %

- Ecuador - 3.2 %

- Indonesia -10.5 %

- Nigeria - 5.5 %

- Colombia - 2.1 %

-

Recipes

Recipes

-

Products

Products

-

Entertaining

Entertaining

-

Chefs

Chefs

-

Hints & Tips

Hints & Tips

-

Glossaries

Glossaries